4 Ways Automotive Manufacturers Can Improve Processes with a CMMS

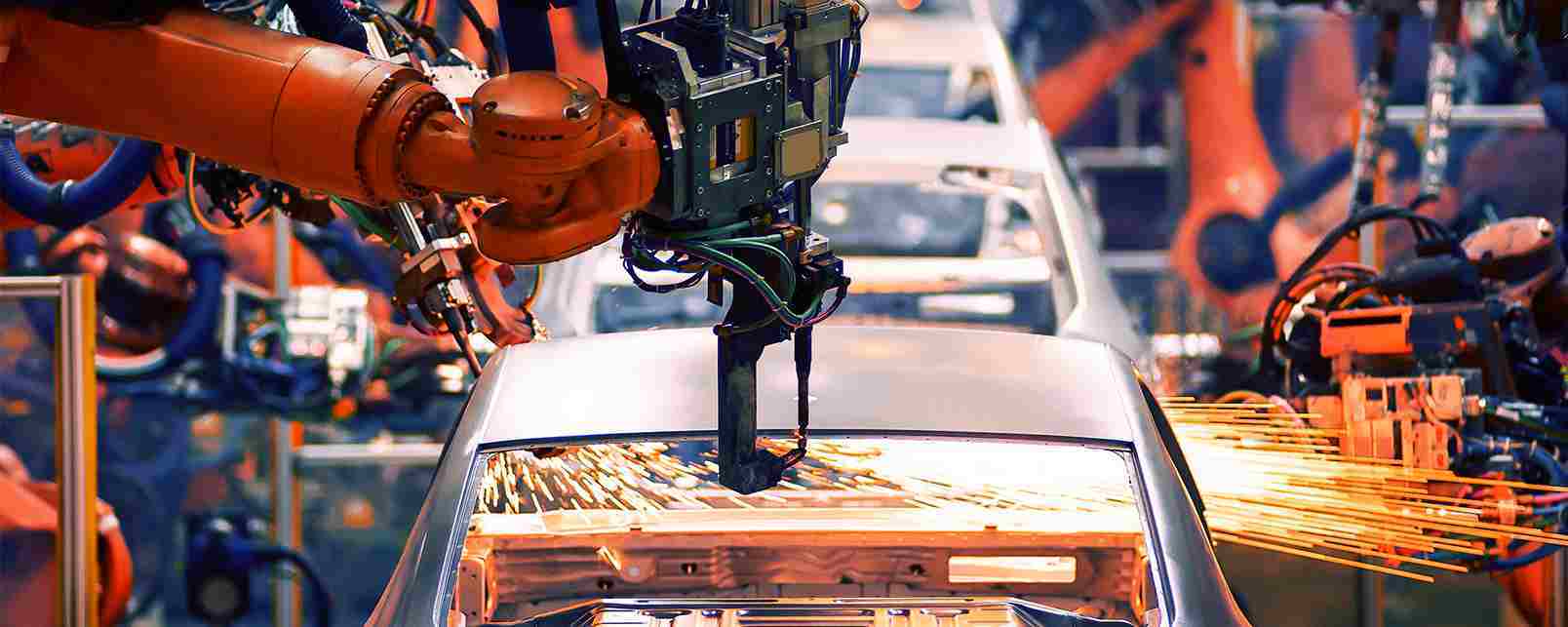

Automakers are always looking for ways to streamline operations, improve communications, and create safe, smart vehicles. A CMMS can help.

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Support

Looking for access to technical support, best practices, helpful videos, or training tools? You’ve come to the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

The right CMMS can help your organization minimize downtime and extend asset life. Here's how.

The manufacturing industry is the sixth largest employer in the United States. In 2017, the manufacturing industry contributed 11% to the Gross Domestic Product for the economy. Because of this, a solid maintenance strategy is critical for manufacturing facilities to perform at peak performance and meet customer demands.

Unplanned downtime in the delivery and production process can cost maintenance managers significant time and money.

With a CMMS, maintenance managers can perform routine maintenance throughout the manufacturing plant that extends asset life, and prevents and predicts equipment failures.

Read on to learn three ways a CMMS helps maintenance managers decrease downtime and improve asset management.

Equipment breakdowns can lead to costly repairs, plant downtime and less overall production. Because of this, asset management is an important task that can save maintenance managers time and money.

With a CMMS, asset management is simple. It gives managers the ability to manage assets from different locations in one central hub. This increases the accuracy and effectiveness of storing information about assets. Beyond that, asset management provides managers with the visibility to monitor equipment performance and functionality. With this insight, manufacturers are able to schedule maintenance visits to inspect and repair equipment as needed.

Asset management can have a major impact on a manufacturing plant’s productivity and service levels, decreasing downtime.

A manufacturing plant has thousands of machines across different locations and departments. Failing to keep assets functioning properly can cause unforeseen delays in the manufacturing process, as well as increased technician overtime and spending.

Preventive maintenance (PM) enhances asset performance by increasing uptime. This is because PM schedules provide managers with the ability to easily plan for maintenance before a breakdown even occurs. This saves a manufacturing plant money because efforts are focused primarily on preventing equipment failure rather than responding to emergencies. As a result, maintenance teams have less unplanned downtime, overtime hours or emergency inventory orders.

From servicing assets to managing various buildings to overseeing operations, maintenance managers and technicians have a big job to fulfill. In order to maintain production without interruption, a manufacturing CMMS provides much-needed transparency into maintenance operations with automated reporting. Automated reporting helps managers gain a transparent look into KPIs, and collect the data they need to make informed decisions.

Automated reporting features include:

With automated reporting, maintenance managers are able to collect data on KPIs like response times, technician efficiency or top used inventory. This helps managers make informed decision to ensure the plant is operating at peak condition and weed out any underperforming assets or departments.

Ready to learn how your manufacturing plant can decrease downtime and improve asset health? Download our ebook, A Manufacturer’s Guide to Preventive Maintenance with a CMMS, for more information.

Automakers are always looking for ways to streamline operations, improve communications, and create safe, smart vehicles. A CMMS can help.

Maintenance management in the public sector is all about ensuring uptime and maintaining effective resource management. A CMMS can help.

Looking to improve your Overall Equipment Effectiveness (OEE)? Here's how Maintenance Connection can help make that happen.

Subscribe to stay up to date with our latest news, resources and best practices