How Lucky Eagle Casino Reduced Maintenance Costs with a CMMS

Learn how Lucky Eagle Casino streamlined work order management and reduced maintenance costs with Maintenance Connection.

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Support

Looking for access to technical support, best practices, helpful videos, or training tools? You’ve come to the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

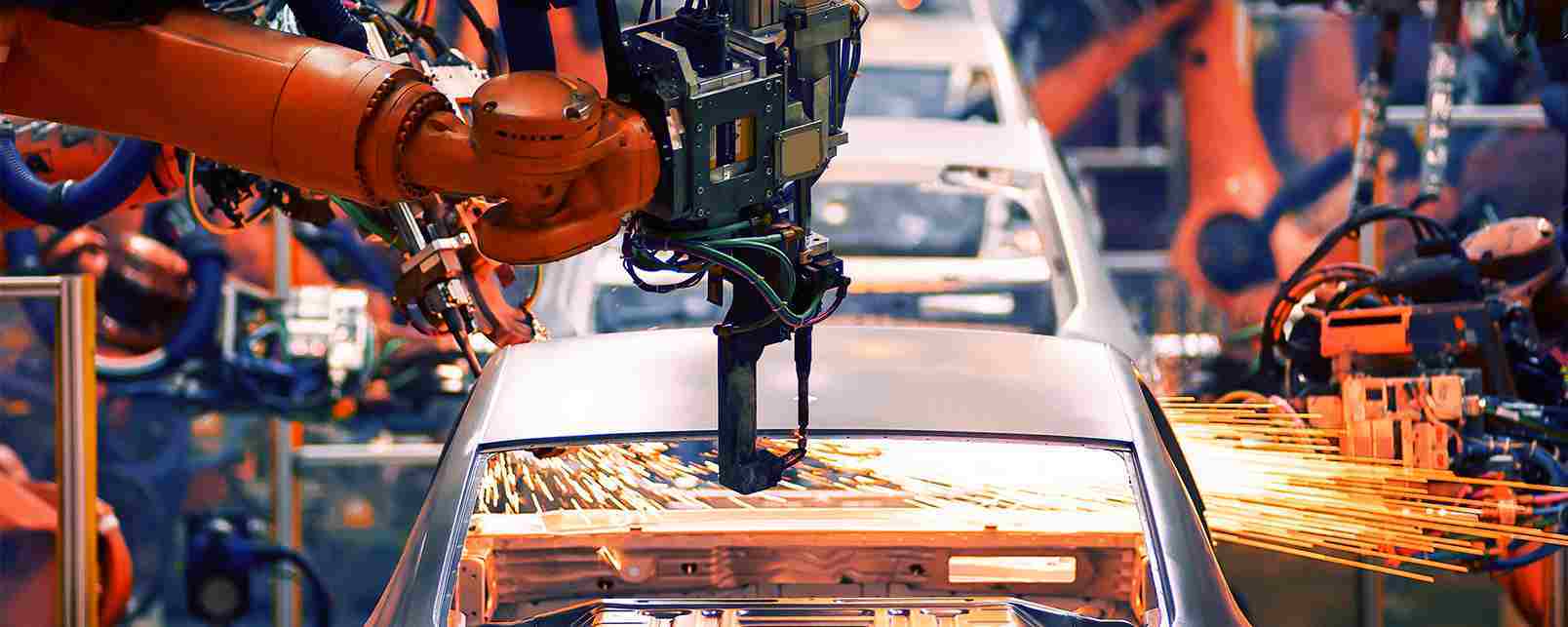

Automakers are always looking for ways to streamline operations, improve communications, and create safe, smart vehicles. A CMMS can help.

The frequency of recalls in recent years has contributed to a significant, yet unnecessary expense for automotive manufacturers. U.S. vehicle recalls hit an all-time high this decade, reaching a record of 51.2 million vehicles over 868 separate recalls.

As automakers strive to develop cleaner, safer, smarter and more energy-efficient vehicles, manufacturers need visibility into the supply chain and production process. To mitigate risk, automotive manufacturers turn to computerized maintenance management software (CMMS) to streamline operations and improve internal communications.

Below, learn four ways a CMMS benefits automotive manufacturers through work order tracking, automated reporting and preventive maintenance.

A major pain point for automotive manufacturers is inefficiencies in the supply chain. In the automotive industry, time is money, and overcoming the risk of costly asset downtime is critical.

To streamline operations, automotive manufacturers rely on a CMMS to track work order status. With a global supply chain, it becomes increasingly difficult for manufacturers to oversee operations and maintain safe, efficient environments across plants. Plus, with work orders piling up for thousands of assets across multiple locations, the maintenance team may have delayed response times and increased downtime without a properly tracked maintenance strategy.

Utilizing a CMMS helps manufacturers communicate with operators, inspectors, suppliers and the maintenance team fulfilling the requests both within the facility and offsite.

Plus, maintenance technicians on the floor are able to update work order processes with a CMMS to keep documentations robust and detailed. And, this gives the manufacturer a clear view into when an asset will be up and running again to continue on production schedules.

A single car has about 30,000 parts. With that type of volume, error is possible throughout the production process. To improve effective production, automotive manufacturers utilize a CMMS to organize assets and benchmark performance across all locations.

Beyond that, a CMMS functions as a maintenance database to improve company-wide visibility. Through auto-generated email reports, the entire team is able to spot key performance trends and make profit-conscious decisions. As a result, the maintenance team is able to report on top-performing machines, technician efficiency or assets that may need replaced based on CMMS data.

Given that the automotive industry is a global manufacturing sector with several tiers of suppliers, there are strict guidelines and regulations that must be followed when producing vehicles.

With a CMMS, automotive manufacturers are able to prove compliance with environmental, safety and import regulations and standards, such as IATF 16949:2016. This standard is an ISO technical specification aimed at the development of a quality management system that provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the automotive industry.

A CMMS serves as an internal database for maintenance teams to protect assets while meeting outside regulations. Beyond that, a CMMS generates preventive maintenance schedules to improve the uptime, performance, efficiency and longevity of assets.

Downtime seriously affects the automotive industry, as it increases technician overtime, escalates budgets, causes emergency inventory orders and reduces the lifespan of equipment. However, according to Reliable Plant, automotive manufacturers spend nearly 90% of their time on emergency breakdown repairs.

With a preventive maintenance program, manufacturers are able to plan for maintenance as needed, improving internal communications and operations. Servicing equipment on a predetermined schedule allows the maintenance team to prevent downtime from occurring. Not only does this enhance the lifespan of regularly used equipment, but it also leads to less replacement costs.

A PM schedule also reduces the number of emergency work orders. As a result, this lowers technician overtime and overall maintenance costs. Routine maintenance lessens large-scale repairs, which improves the safety and quality of conditions for everyone involved in the manufacturing process.

Plan your investment with our CMMS pricing guide and ROI calculator.

Learn how Lucky Eagle Casino streamlined work order management and reduced maintenance costs with Maintenance Connection.

Learn how a successful CMMS implementation can help you overcome reactive maintenance inefficiencies and maximize your overall return on investment ...

How comprehensive asset intelligence, effective preventive maintenance, and efficient labor scheduling can lead to success in the chemical industry.

Subscribe to stay up to date with our latest news, resources and best practices