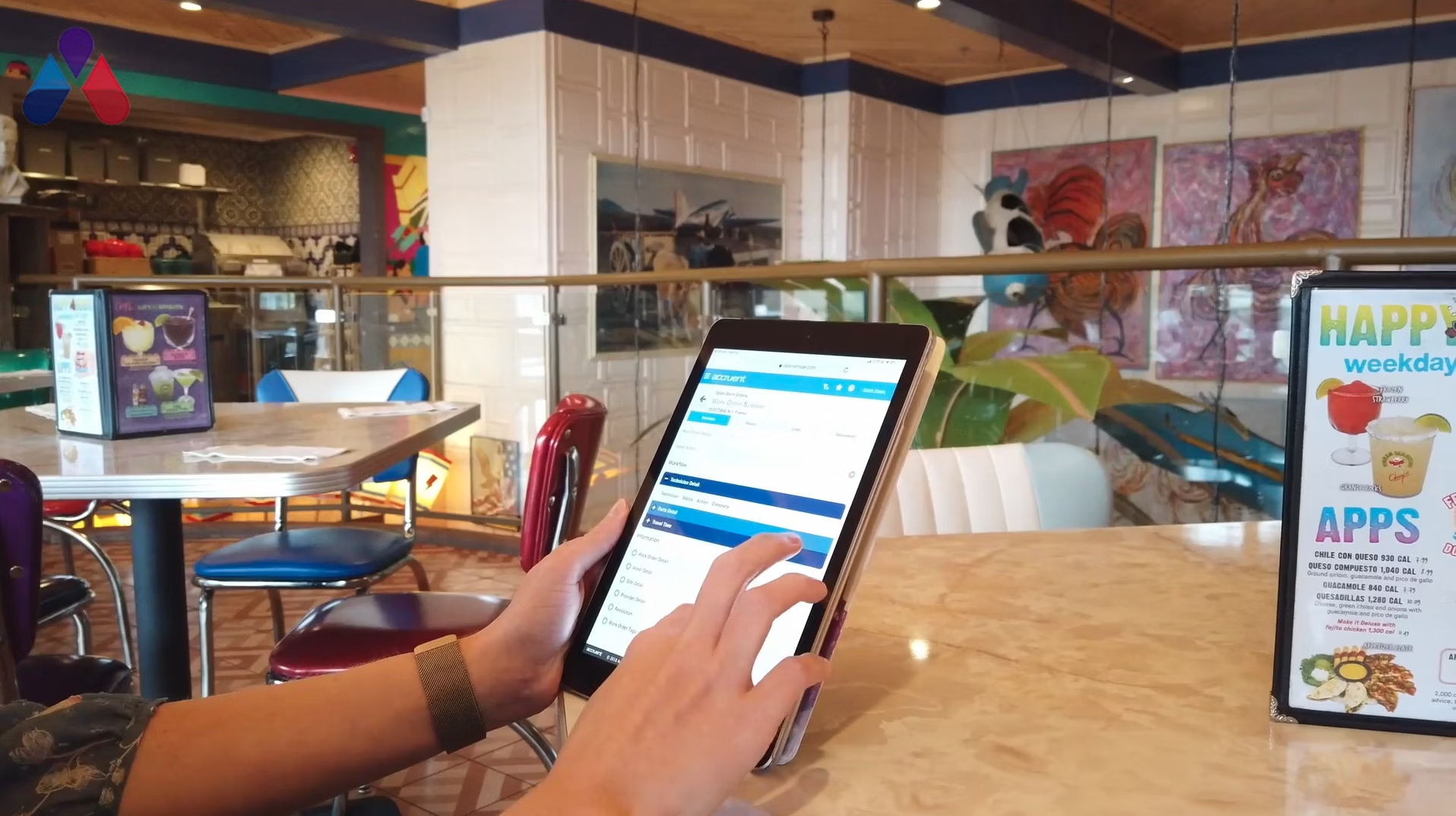

Chuy's

Discover how Chuy's improved its work order management system with Accruent's CMMS to create efficiencies, cut costs and reduce equipment downtime by ...

Solutions

Workplace Management Solutions

Real Estate Management Solutions

Maintenance Management Solutions

Energy Management Solutions

Engineering Document Management Solutions

Asset Management Solutions

Automate campus scheduling for classes, meetings, and exams with our EMS software.

Plan and manage conferences effortlessly with EMS software to impress guests and streamline operations.

Boost workplace flexibility and maximize space use with seamless desk and room booking.

Organize workplace or campus events smoothly, creating memorable experiences.

Optimize workspace, manage allocations efficiently, and reduce costs with our space management solutions.

Deliver projects on time and within budget by improving communication, collaboration, and efficiency with our software.

Streamline lease accounting for ASC 842, IFRS, and GASB compliance.

Manage leases efficiently by tracking key dates, analyzing costs, and ensuring compliance.

Centralize data and analytics for better insights, faster negotiations, and revenue growth.

Centralize facility and asset maintenance, automate work orders, and ensure compliance with our CMMS software.

Extend asset life, reduce downtime, and prevent costly repairs with data-driven monitoring.

Prevent equipment failures and extend asset life by detecting and addressing issues early.

Make sustainable, cost-efficient energy decisions by monitoring and optimizing power consumption.

Remotely monitor and control equipment with real-time data to predict issues, boost efficiency, and reduce downtime.

Easily share and collaborate on documents, creating a single source of truth for engineers and contractors.

Manage and analyze assets across their lifecycle to schedule maintenance, reduce downtime, and extend lifespan.

Improve visibility, automate work orders, and ensure compliance for efficient facility and asset management.

Resources

Browse our full library of resources all in one place, including webinars, whitepapers, podcast episodes, and more.

Support

Looking for access to technical support, best practices, helpful videos, or training tools? You’ve come to the right place.

About Accruent

Get the latest information on Accruent, our solutions, events, and the company at large.

Table of contents

Skogen’s Festival Foods is more than just a grocery store. Headquartered in Onalaska, Wisconsin, the employee- and family-owned company prides itself on providing high quality products and offering guests an exceptional shopping experience. Festival Foods has fueled a culture of excellence, from positively impacting communities to ensuring quality products and an exceptional experience, and is a place where family, fun and food come together.

Years in Business

Stores

Annual Sales

Tagged Assets

With the Accruent solution, we see increased equipment uptime and performance. Centralized decision making and equipment control saves our associates time, reduces energy costs, and gives us the tools that we need to better manage our assets in a rapidly changing world of grocery retail."

— Cody Sandahl, Energy and Material Recovery Manager

Skogen’s Festival Foods saw an opportunity to save money and to better manage assets with more focus and more consistency through the improved tracking of store equipment and repairs. The company also wanted to develop a refrigerant replacement strategy to improve the control and management of refrigerant costs while holding vendors fully accountable. In addition, the retailer was experiencing frustrations with its alarm monitoring program due to a high volume of superfluous calls.

Accruent provides us with a convenient platform in which our asset data can be managed from one pane of glass. The consistent maintenance program across our complete portfolio frees up time for all of our in-store associates to do what they do best, which is take care of our guests."— Festival Foods

Skogen’s Festival Foods chose Accruent’s suite of solutions for facility and asset management, refrigerant management and IoT remote alarm monitoring. The grocer first implemented vx Maintain to centrally manage the full workflow of reactive and planned activities, including work orders, warranties and invoices. It then deployed vx Sustain to manage all events for refrigeration and HVAC systems, including gas types and volumes, leak history and technician certifications. Lastly, it deployed vx Observe for remote monitoring and control of multiple equipment types.

We’ve virtually eliminated the noise of overactive alarms. Out of 300,000 raw alarms, vx Observe determined fewer than 9,000 were valid, leading to a dramatic decrease in vendor calls while ensuring we address critical failures."— Festival Foods

By implementing Accruent, Skogen's Festival Foods was able to revamp and modernize its maintenance program, ensuring consistency across its portfolio and allowing for optimal energy consumption. The integration of vx Maintain and vs Observe means the company can link alarms with costs to make better repair and replace decisions on equipment while preventing further upstream alarms for the same condition. And the use of vx Sustain enables it to develop a refrigerant replacement strategy as the company shifts toward lower GWP refrigerants while holding vendors accountable for fixing leaks.

Discover how Chuy's improved its work order management system with Accruent's CMMS to create efficiencies, cut costs and reduce equipment downtime by ...

Learn how Amtrol-Alfa uses Meridian EDMS to maintain ISO 9001 compliance, streamline document control, and improve performance with centralized ...

Discover how Maintenance Connection helped Watson-Marlow enhance operational efficiency, streamline workflows, and drive collaboration across teams.

Subscribe to stay up to date with our latest news, resources and best practices.

* To unsubscribe at any time, please use the “Unsubscribe” link included in the footer of our emails.